A zero degree ratchet, also known as a 90-tooth ratchet, is a type of ratcheting wrench that offers a smaller swing arc, allowing for easier access in tight spaces. The name “zero degree” comes from the fact that the ratchet has a 4-degree swing arc, which is significantly smaller than traditional ratchets that typically have a 72-tooth mechanism with a 5-degree swing arc. This means that with a zero degree ratchet, you can turn the fastener with just a 4-degree movement, making it ideal for working in confined areas where a larger swing arc would be impractical.

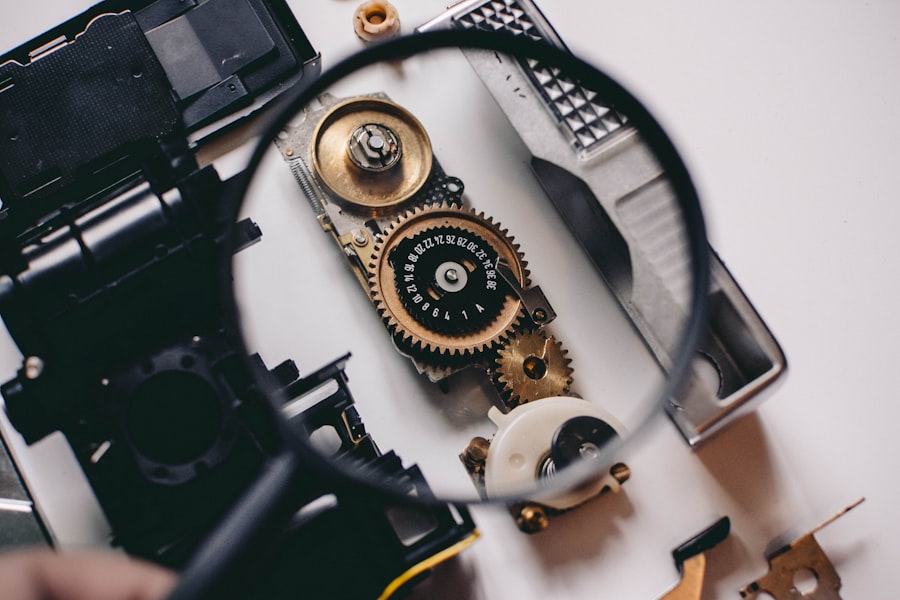

The zero degree ratchet works by using a gear and pawl mechanism to allow for unidirectional motion. When the handle is turned in one direction, the gear engages with the pawl, allowing the ratchet to turn the fastener. When the handle is turned in the opposite direction, the pawl disengages from the gear, allowing the handle to be repositioned without turning the fastener. This mechanism allows for quick and efficient tightening or loosening of fasteners without having to remove and reposition the wrench for each turn.

Key Takeaways

- The zero degree ratchet is a tool that allows for rotation in tight spaces and at any angle, making it highly versatile.

- Using a zero degree ratchet in your tool kit can increase efficiency and productivity, especially in confined spaces.

- To use a zero degree ratchet effectively, it’s important to apply the right amount of force and to use the correct size and type of socket.

- When choosing a zero degree ratchet, consider factors such as the size, material, and durability to ensure it meets your specific needs.

- Regular maintenance and care, such as cleaning and lubricating, are essential for prolonging the lifespan of your zero degree ratchet.

The Benefits of Using a Zero Degree Ratchet in Your Tool Kit

There are several benefits to using a zero degree ratchet in your tool kit. One of the main advantages is its ability to access tight spaces that would be difficult or impossible to reach with a traditional ratchet. The smaller swing arc allows for more precise movements in confined areas, making it an essential tool for mechanics, technicians, and DIY enthusiasts working on cars, machinery, or appliances.

Another benefit of the zero degree ratchet is its efficiency. With a smaller swing arc, you can quickly tighten or loosen fasteners with minimal effort. This can save time and energy, especially when working on projects that require repetitive movements. Additionally, the zero degree ratchet’s ability to work in tight spaces can also reduce the risk of damaging surrounding components, as there is less chance of accidentally hitting nearby parts while turning the wrench.

Tips and Techniques for Using the Zero Degree Ratchet Effectively

When using a zero degree ratchet, it’s important to keep a few tips and techniques in mind to ensure efficient and safe operation. First, always make sure to use the correct size socket for the fastener you are working on. Using an improperly sized socket can lead to slippage and potential damage to the fastener or the socket itself.

Additionally, when working in tight spaces with a zero degree ratchet, be mindful of your hand placement and body positioning to avoid injury. It’s important to have a firm grip on the handle and to position yourself in a way that allows for proper leverage without straining your muscles or joints. If possible, use extensions or swivel adapters to further enhance the versatility of the zero degree ratchet and reach even more challenging areas.

Choosing the Right Zero Degree Ratchet for Your Needs

When choosing a zero degree ratchet for your tool kit, there are several factors to consider. First and foremost, consider the quality and durability of the ratchet. Look for reputable brands known for producing high-quality tools that can withstand heavy use and provide reliable performance.

Additionally, consider the size and weight of the ratchet, as well as the comfort of the handle grip. A comfortable grip can make a significant difference in reducing hand fatigue during extended use. It’s also important to consider the range of available socket sizes and accessories that are compatible with the ratchet, as this will determine its versatility for different types of fasteners and applications.

Maintenance and Care for Your Zero Degree Ratchet

To ensure the longevity and performance of your zero degree ratchet, proper maintenance and care are essential. Regularly inspect the ratchet for any signs of wear or damage, such as worn teeth or loose components, and address any issues promptly to prevent further damage.

Keep the ratchet clean and free of debris by wiping it down after each use and storing it in a clean, dry environment. Lubricate the moving parts of the ratchet as needed to ensure smooth operation and prevent rust or corrosion. Additionally, periodically check and tighten any screws or bolts on the ratchet to maintain its structural integrity.

Unlocking the Versatility of the Zero Degree Ratchet: Applications in Different Industries

The zero degree ratchet’s versatility makes it an invaluable tool in various industries. In automotive repair and maintenance, mechanics rely on zero degree ratchets to access hard-to-reach fasteners in engines, transmissions, and other components. The precision and efficiency of the zero degree ratchet also make it popular among aerospace technicians working on aircraft engines and avionics systems.

In construction and carpentry, the zero degree ratchet is used for assembling furniture, installing fixtures, and tightening bolts in confined spaces. Electricians and plumbers also benefit from the compact design of the zero degree ratchet when working on electrical panels or pipe fittings in tight areas. Additionally, hobbyists and DIY enthusiasts find the zero degree ratchet useful for various home improvement projects that require working in cramped spaces.

The Future of Zero Degree Ratchet Technology: What to Expect

As technology continues to advance, we can expect to see further innovations in zero degree ratchet design and functionality. Manufacturers may develop new materials and manufacturing processes to create lighter yet more durable ratchets that offer even greater precision and efficiency. Additionally, advancements in ergonomics and handle design may further enhance user comfort and reduce fatigue during prolonged use.

Furthermore, with the increasing demand for environmentally friendly tools, we may see developments in eco-friendly lubricants and materials used in zero degree ratchets to reduce their environmental impact. As industries continue to evolve, zero degree ratchets are likely to become even more specialized for specific applications, offering tailored solutions for professionals across various fields.

In conclusion, the zero degree ratchet is a versatile and efficient tool that offers numerous benefits for professionals and DIY enthusiasts alike. Its compact design and precise functionality make it an essential addition to any tool kit, allowing for easier access in tight spaces and quicker fastener tightening or loosening. With proper maintenance and care, a high-quality zero degree ratchet can provide reliable performance for years to come. As technology continues to progress, we can expect further advancements in zero degree ratchet design and functionality, further enhancing its utility across various industries.

Sure, here’s a paragraph that mentions a related article to zero degree ratchet and includes a link to the article:

If you’re interested in learning more about zero degree ratchet and its applications in mechanical engineering, be sure to check out the insightful article “Understanding the Mechanics of Zero Degree Ratchet” on The Writer Lingua. This article delves into the principles behind zero degree ratchet and how it is used to improve the efficiency of various mechanical systems. Whether you’re a student studying engineering or a professional in the field, this article provides valuable insights into this fascinating concept.

FAQs

What is a zero degree ratchet?

A zero degree ratchet is a type of ratchet tool that allows for operation in tight spaces where a traditional ratchet may not fit. It has a head that is designed to operate at a 0-degree angle, allowing for easier access in confined areas.

How does a zero degree ratchet work?

A zero degree ratchet works by using a gear and pawl mechanism to allow for unidirectional motion in tight spaces. The head of the ratchet is designed to operate at a 0-degree angle, allowing for easier access in confined areas.

What are the benefits of using a zero degree ratchet?

The main benefit of using a zero degree ratchet is its ability to operate in tight spaces where a traditional ratchet may not fit. This can make it easier to access and work on fasteners in confined areas, saving time and effort.

What are some common applications for a zero degree ratchet?

A zero degree ratchet is commonly used in automotive repair, machinery maintenance, and other applications where access to fasteners in tight spaces is required. It is also popular among mechanics and technicians who work in confined areas.

Are there any limitations to using a zero degree ratchet?

While a zero degree ratchet is designed to operate in tight spaces, it may not be suitable for all applications. It is important to consider the torque and strength requirements of the job before using a zero degree ratchet, as it may not be as powerful as a traditional ratchet.